Triflex Aids Rapid Expansion of Manchester Airport Terminal 2

Installation of Triflex’s PMMA Took Place During Winter Months, Avoiding Further Delays

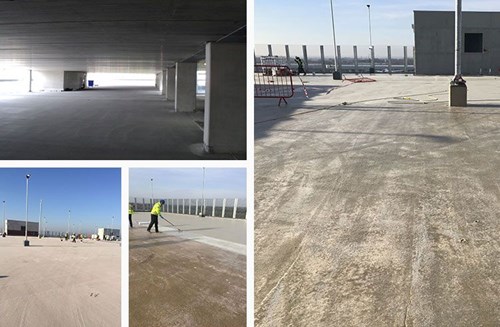

At Terminal 2 of Manchester airport, the new 3,800 space car park has opened ahead of schedule, following the application of Triflex’s PMMA waterproofing solution by Mike Thelwell Flooring Ltd. during the winter months.

10,000m² of Triflex ProPark waterproofing has been applied to the top deck of the car park between November and March despite cold temperatures. The system, accredited to EN 1504-2, will provide the highest levels of performance and crack bridging technology. This will ensure long life at this 3,800 space car park that will play a vital role in the rapid expansion of Manchester Airport as Terminal 2 passenger capacity rises from 27 million to 55 million visitors per year.

To accommodate the rising passenger numbers, Manchester airport is investing £1bn to more than double the size of Terminal 2. Phase one of the building program had a deadline of April 2019 with Phase 2, a further car park, due to be completed by November 2019.

Due to delays, work on waterproofing the car park top deck for Phase 2 began in November. This ruled out most cold applied liquid waterproofing systems, especially those based on polyurethane (PUR) which require the concrete substrate to be at least 9°C and would take 12 hours or more to cure.

The specified system also had to meet strict performance criteria to EN 1504-2 so that it would provide a durable waterproofing system, protecting the concrete structure for years to come and a safe durable floor, for the millions of vehicles and pedestrians that will use it every year. As part of this criteria, it had to demonstrate the highest crack bridging technology available to cope with any movement in the structure.

Lastly, hard-wearing line markings would need to be applied to clearly designate vehicle parking areas, the direction of travel and pedestrian walkways for safety.

Approved Contracting Partner Mike Thelwell Flooring proposed using the Triflex ProPark system as it meets the necessary EN 1504-2 accreditation and dynamic crack bridging requirements. Based on PMMA technology, the system can be applied at temperatures down to 0°C. This allows the system to be applied in shorter weather windows between rain or snow, maximizing the available installation time. It cures in just one hour allowing it to be overcoated or open to foot traffic quickly, ensuring rapid progress on-site.

Exposed ramps up to the top deck had emery aggregate added to aid vehicle grip and the parking areas were finished in a darker color to the driving areas to help visually segregate them. Markings were applied using Triflex Preco Line 300 for bays and wayfinding, and Triflex Cold Plastic for line markings, providing a long term and clearly marked solution for parking, traffic direction, and pedestrian walkways.

Mike Thelwell, from Thelwell Flooring, said: “The only way that the waterproofing could be completed during the winter months was by using a Triflex PMMA based system, it would have been impossible with a polyurethane (PU) system. Even using this PMMA system there were times when the temperature of the concrete on the top deck was below freezing and we had to use large scaffold canopies with electric heaters to maintain progress during, particularly cold periods.

“Even if an area did get damaged due to moisture, it was easy to repair as a patch could simply be cut out and then a new layer applied over the top.”

About Triflex

Triflex is the leading European specialist in liquid waterproofing products and cold plastics. Our  high-quality systems provide reliable and lasting solutions for waterproofing roofs, balconies, and parking decks. In addition, we prove our technology leadership time and again with a whole range of special solutions. Triflex markings set the standard on roads and cycle paths, in factories and multi-story car parks.

high-quality systems provide reliable and lasting solutions for waterproofing roofs, balconies, and parking decks. In addition, we prove our technology leadership time and again with a whole range of special solutions. Triflex markings set the standard on roads and cycle paths, in factories and multi-story car parks.

We deliver individual solutions worldwide from our production facilities in Minden, Germany. We can boast more than 40 years of experience in the market. Reliability, focus on service and innovation are the values we work by every day in our customers’ interest.

Comments

There are no comments yet for this item

Join the discussion